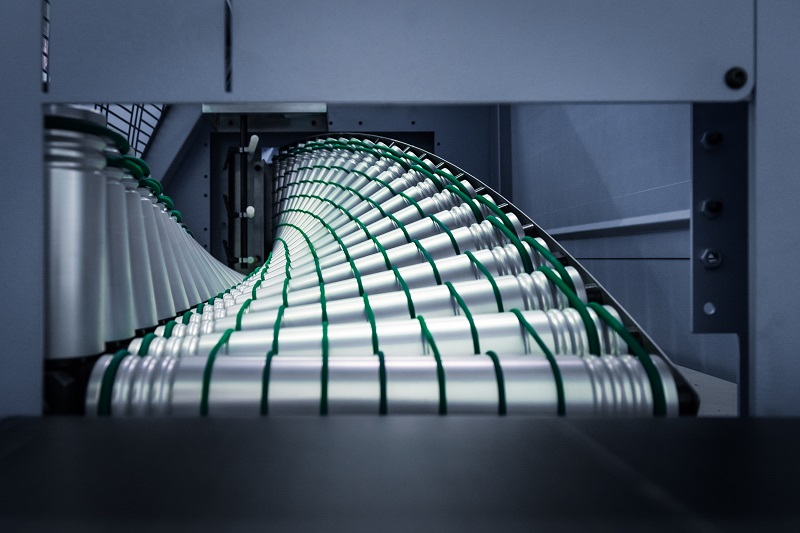

Conveyor rollers or idler rollers are an integral part of any conveyor system. They run beneath the belt to assist, among other roles, with material weight support and effects. There are several varieties of roller materials and styles, which are built to meet specific application requirements. They vary in shape, weight, thickness, lagging/coating content, and more.

Steel rollers (including mild and stainless steel) tend to be the top option for many industries that use conveyor systems. In some cases, however, plastic may provide a suitable solution. When deciding on steel or plastic rollers for your conveyor belt. There are several important factors to consider. These include which products are being handled, the environment your conveyor system works in, the scale of your operations, costs, and more.

It is therefore important to note that stainless steel conveyor rollers are a commonly used alternative to plastic rollers in this specific application. Easy to clean, Stainless steel is resistant to corrosion and a common option for environments with strict hygiene conditions. In general, steel conveyor rollers outperform plastic rollers considerably due to their reliability in heavy industrial applications.

Type of Materials

The material moved by the conveyor system plays a significant role in determining whether to use steel or plastic. When the materials are big or strong, steel rollers do a better job to withstand their weight and impact force. Plastic rollers are more suitable for lightweight materials because they are not as durable as steel.

Nevertheless, corrosive materials can cause wear and break down mild steel rollers. Stainless steel or aluminum steel rollers are an alternative to mild steel since they are corrosion resistant. Plastic rollers are also a corrosion-free option.

Operation setting

Plastic rollers can also be harmful in conditions that are at high temperatures. Steel rollers can endure intense heat, in terms of both the operating atmosphere and the temperature of the materials being transported.

When exposed to high temperatures, plastic has a higher level of thermal expansion as compared with steel.

The operating temperature must be carefully considered when using plastic rollers otherwise you can risk roller failure due to a warp.

Size of operation

Due to their limited longevity and strength, plastic conveyor rollers can be better suited to smaller conveyor operations such as in the food industry. However, many food manufacturing industries now opt for stainless steel rollers over plastic rollers for their food-grade quality and also because they are easy to clean and are corrosion-free.

Due to their usually larger scale, higher efficiency, and long-lasting strength, larger operations, such as in the mining industry, would do better with steel rollers.

Cost

In almost all cases, steel rollers are cheaper to manufacture than plastic rollers.

Steel rollers have long been used as the standard in the mining industry and are manufactured in economies of scale. The steel rollers’ production process has been continuously developed and innovated.

Plastic rollers are still a relatively new product and are still a long way from innovation.

Design advantage

Plastic is not as solid or robust as steel as the base material, thus plastic rollers are inherently weaker than steel rollers. However, plastic rollers have the benefit that “pizza wheeling” does not harm the belt.

For both steel and plastic rollers, a simple design adjustment can be made to avoid pizza wheeling. If you raise the size of the roller side walls, there is no pizza wheeling because the side walls are thicker and not a thin, sharp edge anymore. This shift in design adds extra expense as more material is needed to thicken the side walls.

Plastic rollers are popular for very lightweight conveyors and particularly for food applications, or where a mild-steel roller can scratch or label the surface of the product being carried. Similar to a sturdier steel or polypropylene rollers, they are fairly brittle. They are, therefore, eminently suitable for loads of a few tens of kilograms.

Plastic conveyor roller proponents appear to be in the food industry or processing plants where the machinery is subject to regular washing and harsh chemical treatments as mandated by FDA and/or FSMA regulations. In such situations, untreated steel can corrode and require replacement.

Select the best conveyor rollers for your requirement

Plastic costs considerably less and are easier to work with during the manufacturing process. As the metal parts are more complex to work with, the price also increases. Steel is difficult to work with and harder to shape than the plastic. A broken plastic conveyor rollers can cause less trouble then the steel rollers.